ENP has the ability to nickel plate many base materials. Along with its huge plating line normally used for plating ferrous metals, ENP has another line dedicated to plating aluminum.

Nickel Plating can be applied to a multitude of base metals including:

| Aluminum |

Heat Treated Steel |

Ceramics |

|

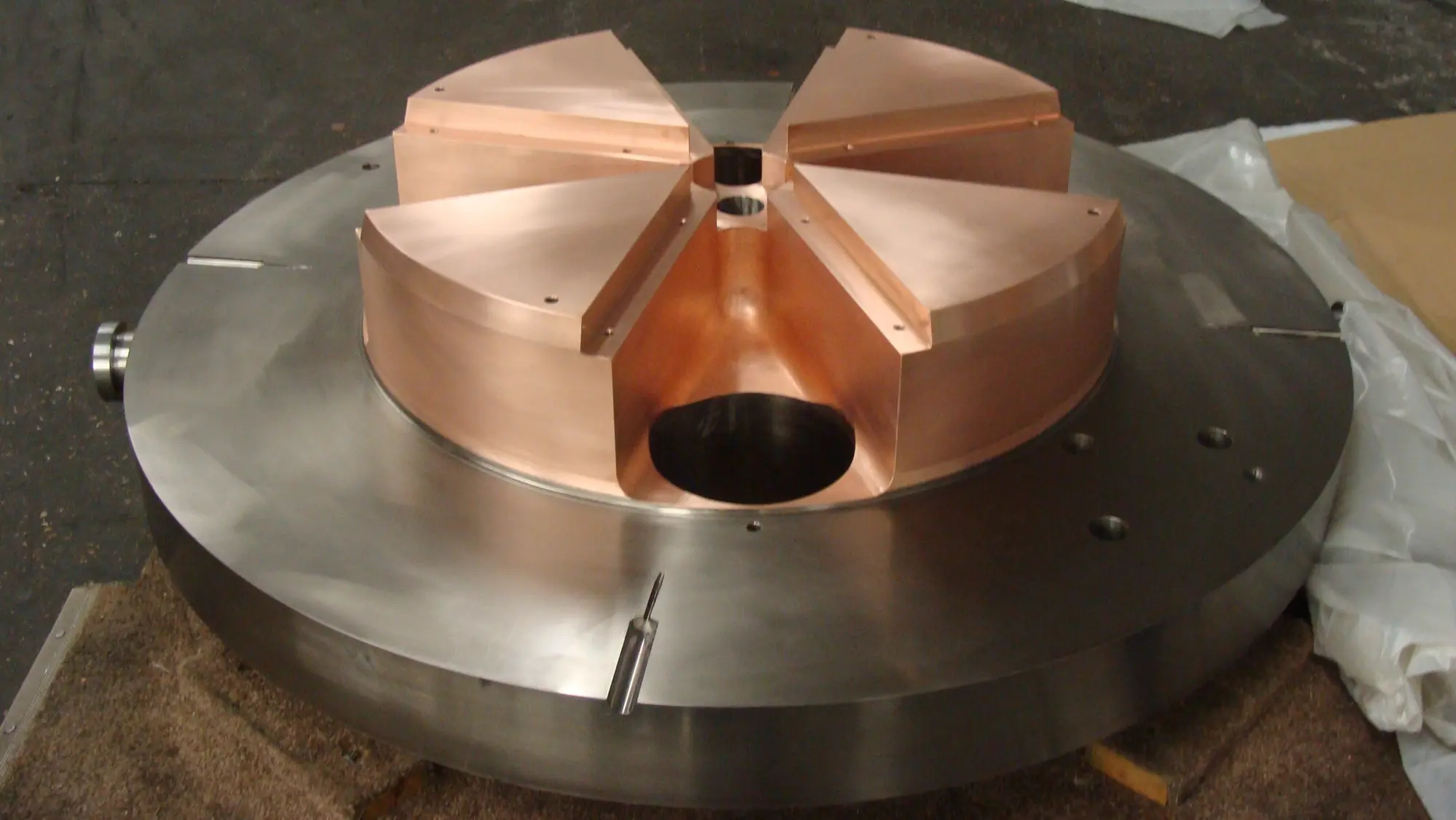

Copper |

Nickel Alloys |

Zinc Die Casts |

|

Copper Alloys |

Steel |

Sintered Metals |

|

Brass |

Stainless Steel |

Plastics |

|

Bronze |

Tool Steels |

Titanium |

Substrate material can greatly influence the nickel deposit properties.

Excellent adhesion of electroless nickel deposits can be achieved on a wide range of substrates, including steel, aluminum, copper and copper alloys. Typical bond strengths reported for electroless nickel on iron and copper alloys range from 50 to 64 kpsi (345 to 441 M Pa). The bond strength on light metals, such as aluminum, tends to be lower, in the range of 15 to 35 kpsi (103 to 241 M Pa) for most alloys.

Heat treatment is commonly employed to improve adhesion of EN on all metals, particularly on light metals such as aluminum or titanium. During this heat treatment diffusion occurs between the atoms of the coating and the substrate.

The brightness and reflectivity of electroless nickel depends on the surface finish of the substrate. In other words, electroless nickel reproduces the finish to which it is applied and is not a filler coating such as chrome.